wire edm machine working principle

In wire EDM a long. This leads to the removal of the material layer.

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

Electrical discharge machining EDM is a process of removing material by exposing it to reoccurring controlled electric discharge.

. This leads to the removal of a material layer. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. It was invented by the former Soviet Union in the last century but China applied this technology to industrial production for the first time.

Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very difficult to be machined by traditional machining processes. The basic principle behind this process is the erosion of the material with a controlled electric spark. Extrusion dies or nozzles and horns can be cut with constantly changing tapers.

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. For this to occur the two electrodes must not come in contact. The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting point of metal materials.

Working Principle and Performance of Wire Electrical Discharge Machining Abstract. This means that the sinker EDM can fabricate pieces with blind features. There is the application of potential difference across the workpiece and the electrode in pulse form.

EDM spark erosion is same as electric spark. Wire EDM machining can cut through the material completely while sinker EDM services are not able to cut completely. The dielectric fluid in this caseusually deionized wateris flushed through the cut as it proceeds again serving to carry off particles and control the sparks.

It works on the thermo-electrical phenomenon. As the electric discharge takes place between an electrodewire and workpiece the thermal energy is generated on a workpiece. Generally there are three types of EDM machines.

Wire cut EDM and sinker EDM both employ the principle of electrical discharge machining what are the differences between them. As the electric discharge takes place between an electrodewire and workpiece the thermal energy is generated on a workpiece. It is suitable for thermoelectric phenomena.

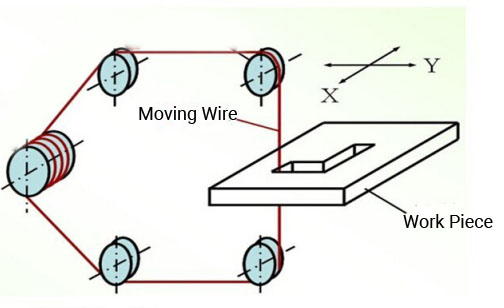

Hole drilling EDM machines. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM.

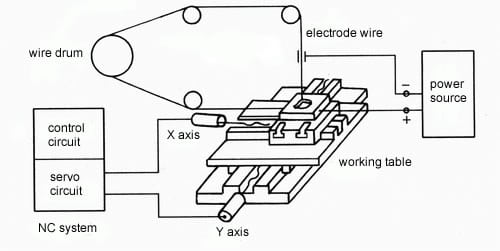

Wire EDM in process Wire EDM machine. However in modern. A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts.

The tool control tool electrode is fed to the workpiece through the gap automatic control system. Die sinker or ram EDM. Wire cut EDM or WCEDM discharges the electrified current by means of a taut thin wire which acts as the cathode and is guided alongside the desired cutting path or kerf.

There are many different specialised types of EDM machine but they generally fall into three separate categories. Small Fast Hole EDM and wire-cut EDM. For example a stamping die can be machined with 14 degree taper or a mold with one degree taper in some areas and two degrees in another with precision.

It works on the thermo-electrical phenomenon. Principle of wire cut EDM 2011-11-04 CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo system to get a certain gap and realize impulse discharging in the working liquid between electrode wire and workpiece. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece.

When performing EDM the tool electrode and the workpiece are respectively connected to the two poles of the pulse power source and immersed in the working fluid or the working fluid is charged into the discharge gap.

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Electric Discharge Machining Wire Edm Youtube

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Edm Find Suppliers Processes Material

Wire Cut Edm Process 2 Download Scientific Diagram

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Edm Machining Wire Edm 101 Sans

Wire Edm Find Suppliers Processes Material

Mechanical Engineering Electrical Discharge Machining Edm Principles

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube

Mas 865 How To Make Something That Makes Almost Anything

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster